Partners and companies within ECCPM develop implementable solutions to propel pharmaceutical manufacturing into the twentyfirst century.

BETTER MANUFACTURING NEEDS BIGGER THINKING

The Drivers for Modernizing Pharmaceutical Manufacturing

- Process and material understanding

- QA / QC strategy

- Real-time release testing

- Predictive modeling

- Regulatory alignment

- Economic alignment

- Human resource/expertise development

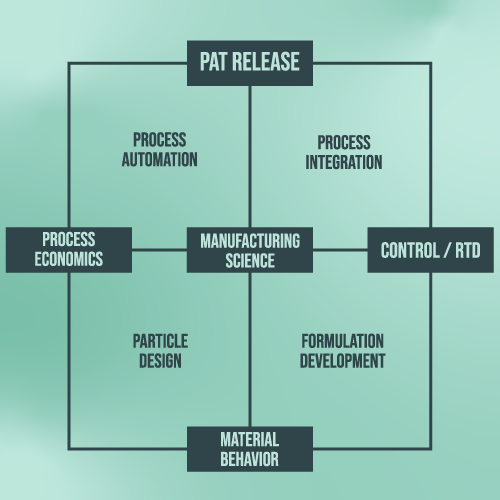

Our Approach to Continuous Manufacturing Development:

- An interdisciplinary team of process, pharmaceutical and chemical engineers and researchers

- A diverse partner matrix consisting of pharma, technology/equipment providers, and academic/scientific collaborators

- A platform for pre-competitive information exchange and networking

- Flexible intellectual property rights (IPR) arrangements to enable a agile and focused exploration of specific interest

Benefits and Expected Outcomes

- Low financial risks to explore new technological options and applications

- Access to RCPE’s long-term experience with continuous and advanced manufacturing, PAT, process control, and predictive modeling

- Exploitation of RCPE’s extensive experience in the advanced manufacturing and (in-line and off-line) characterization

- Access to the most advanced AI-based dissolution prediction models

- Access to the regular ECCPM-organized conferences

- Examination of the impact of continuous manufacturing routes on costs (production, materials, footprint, etc.), efficiency and yield

- Implementation of concepts for integrated quality control strategies

- Utilization of continuous manufacturing knowledge and experience

- Access to consolidated scientific expertise (e.g., simulation, control and process knowhow, RTRT-PAT, and formulation development)

- Access to equipment and instrumentation suppliers

- Access to an international and focused network